- About Us

-

Solutions

EPC Projects

Anaerobic Processes Package

-

Equipments

Project Equipment Package

Processes Equipment Package

Storage Tanks

- Project Reference

- Download

- News

- Contact Us

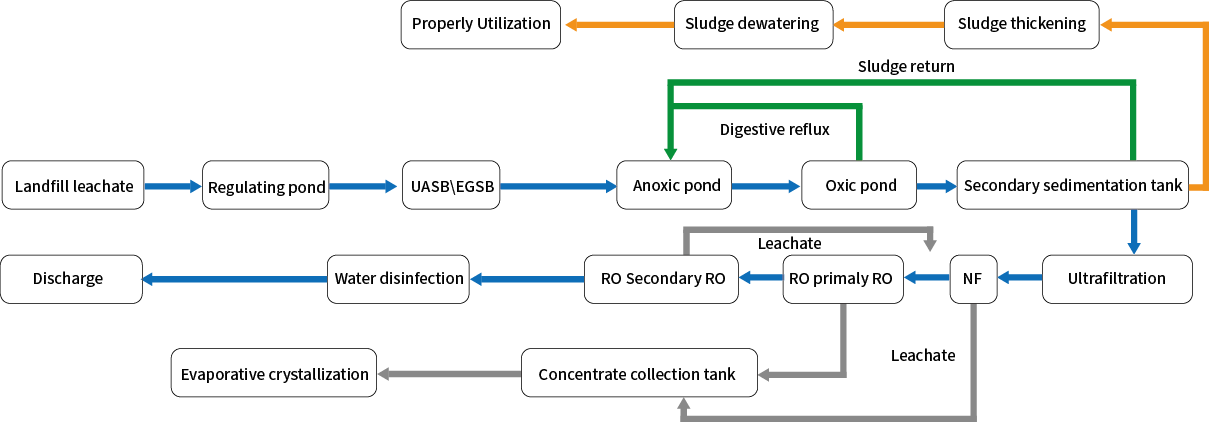

In view of the various problems in the current landfill leachate treatment,Zhengzhong Technology (Center Enamel) adopts the optimal technological solution to achieve the reduction and harmless treatment of landfill leachate by: Pretreatment + Biochemical method + Membrane separation method.The technical solution is based on the premise of stable and continuous discharge that meets the standard, and comprehensively considers the quality and quantity of landfill leachate as well as the economy, rationality and operability of the treatment process. It can deeply remove organic pollutants that are difficult to degrade. In order to improve the effluent standard of sewage treatment and prevent environmental pollution.

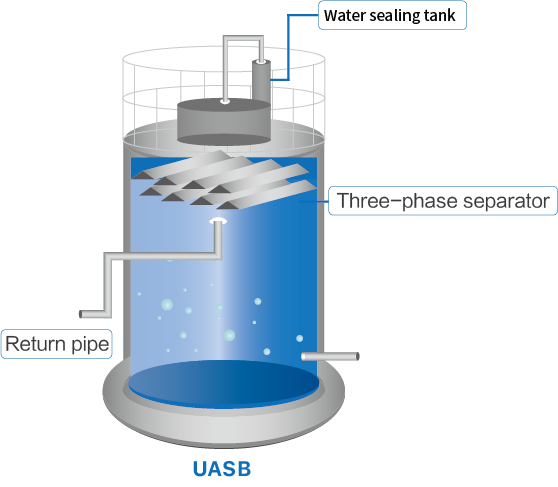

In the landfill leachate anaerobic process, the UASB process (Upflow Anaerobic Sludge Bed) or the EGSB process (Anaerobic Expanded Granular Sludge Bed) is applied. These two kinds of reactors have different volumes and rising speeds of water flow, and the working principle and composition structure are without big differences. Both sludge bed have circulation system, heat preservation and heating system, ladder, platform, etc.

The treatment effect is remarkable

The treatment effect is remarkable

The technology is mature. It can not only remove organic matter and suspended solids in landfill leachate, but also effectively remove ammonia nitrogen and total nitrogen, reduce the number of pollutants and the degree of harm, and ensure that the effluent discharge meets the standard. It is suitable for advanced treatment of landfill leachate.

Low operating cost

Low operating cost

In the landfill leachate treatment project, Center Enamel uses the GFS tank independently developed and produced by ourselves as a modular anaerobic treatment unit to replace the structures of the traditional sewage treatment station, realize modular design and construction, and reduce the area ofthe sewage plant. So that it can reduce the operating costs.

Little secondary pollution

Little secondary pollution

Comprehensive and effective solutions, equipment and technologies. The sludge generated in the entire process is collected, concentrated, centrifuged and dehydrated, and properly disposed of without secondary pollution. Certain measures are taken for the odor emission of facilities and equipment to facilitate the later operation of the project.

Project Location: Hong Kong, China Project time: 2019

Project Location: Liaoning, China Process: UASB

Project Location: Guizhou, China Process: EGSB

Project Location: Poyang, China Process: EGSB

Project Location: Biyang, China Process: EGSB